90% to 99% of Malfunction issues are "User Caused" and not a defect in material or workmanship of the product.

Nobody is taking responsibility for their own lack of knowledge, ability to comprehend directions, or read the instruction manual!

Here is a perfect example from a customer who was well instructed but just wanted to do what they wanted to do, the way they wanted to do it.

Nobody is taking responsibility for their own lack of knowledge, ability to comprehend directions, or read the instruction manual!

Here is a perfect example from a customer who was well instructed but just wanted to do what they wanted to do, the way they wanted to do it.

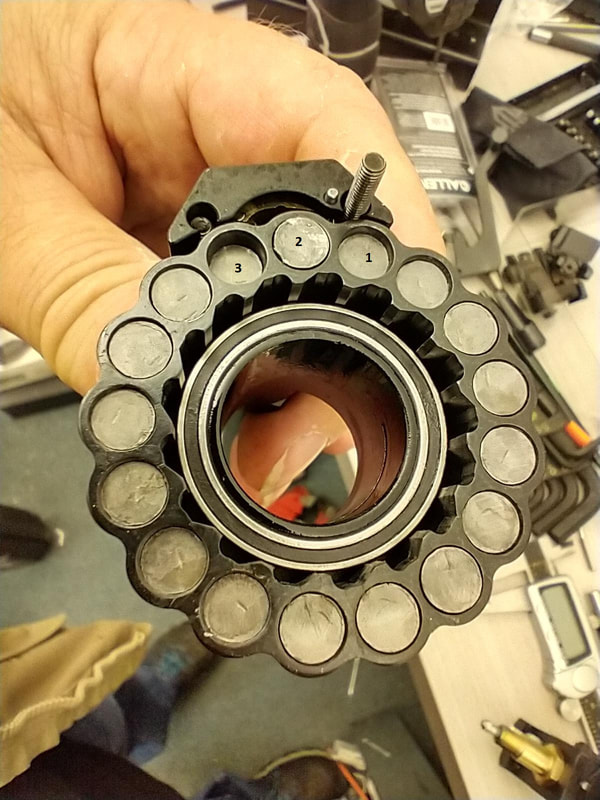

Three issues - Slugs @ Twelve O'Clock

|

Three issues - From the barrel side

|

Slugs not fully set into the magazine - 17 issues!Further proof the slugs weren't properly set into the magazine fully... not a single tip of any slug is up to the forward magazine face. also notice the 3 slugs in my hand... the fell out under their own weight! a snug fit is required or you should unload any sloppy fitting projectiles as they only cause misfire issues.

|

|

The Good - The Bad - and The Ugly

- Only slugs #2 and #3 show proper score marks on the outside diameter from moving forward in the magazine. The Magazine has a type of Riffling to hold the projectile straight. Without proper engagement in this rifling, the slugs will droop, slide and move causing all kinds of accuracy issues and possibilities for jams and misfires. Only the user has control of proper loading and fits.

- #4 and #5 were removed from the magazine showing no score marks indicating improper loading.

This airgun is back together and shooting perfect again. No issues, No Jams, No manufacturers defects. It's shooting pellets and slugs just fine when properly loaded.

First shots after removing the jam, No O-ring failures! Yes there was sideways blowout on the customer during their shooting, Yes there was a full air tank dump down the barrel, all caused by Operator Error, not by any O-Rings! The cause is the Firing valve and/or Magazine seal was being held from closing by improper loading of the magazine. The magazine seal is hard plastic , "Not and O-ring" as much as the back yard, beer-drinking, want-a-be engineers, would have you believe. Another condition that can cause a dump is adjusting the regulator and power wheel past where the springs are under pressure! Again... operator error and ignorance! You will get plenty of power and accuracy with proper adjustments .... not maximum turns on the adjustments, it's just not designed that way. Your air rifle will be more flexible than your ammo. your ammo has limitations you air rifle will be adjusted to accommodate.

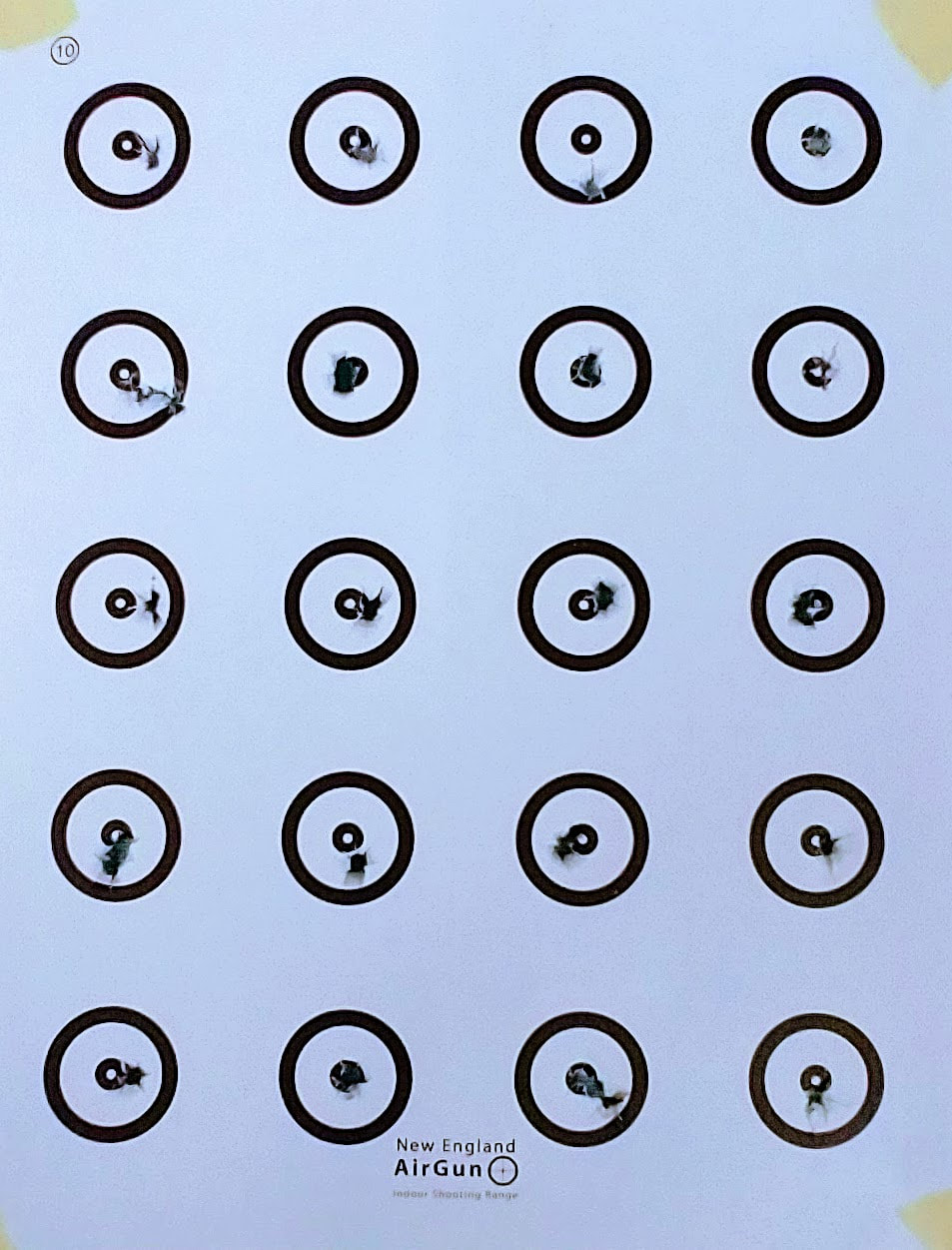

This target was shot with LEAD-FREE Pellets, nothing optimized, all factory settings. There were a few fliers inside of a Quarter @ 50 feet. Imagine what can be accomplished with a quality made JSB or Custom Made Slug that has been fit to the barrel. Some targets had two shots to make up for user twitch or flier pellet. Next thing to do is clean the barrel and optimized the internal regulator and power wheel.

This target was shot with LEAD-FREE Pellets, nothing optimized, all factory settings. There were a few fliers inside of a Quarter @ 50 feet. Imagine what can be accomplished with a quality made JSB or Custom Made Slug that has been fit to the barrel. Some targets had two shots to make up for user twitch or flier pellet. Next thing to do is clean the barrel and optimized the internal regulator and power wheel.

- This air rifle was designed for long range shooting. not the close range we just tested at. ( it can be used for any distance with proper expectations )

- This air rifle was designed with an unchoked barrel for shooting slugs at long distance, but it is also capable of shooting pellets with the limits a pellet can handle.

- This air rifle is infinitely adjustable, that said, improper adjustment and projectile choice will result in inaccuracies and mechanism malfunctions..